Applying 3D-Printed Polymer Substrate Coated with Photocatalytic Film to Efficient Water Purification

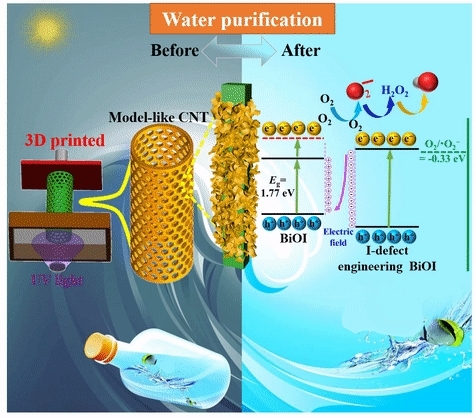

In the face of complicated water purification circumstances, the employment of sheet or retiform substrates coated with bismuth-based photocatalytic coatings may be restricted because of the mismatch in size and shape between environments and substrates. Hence, customized substrates coated with photocatalysts will be welcomed.

Recently, the research team led by Prof. ZHANG Dun from the Institute of Oceanology of the Chinese Academy of Sciences (IOCAS) provided a kind of novel Successive ion layer adsorption reaction (SILAR) in-situ grown bismuth oxyiodide (BiOI) film on 3D-printed polymer substrate for purification application.

The study was published in Separation and Purification Technology on May. 4.

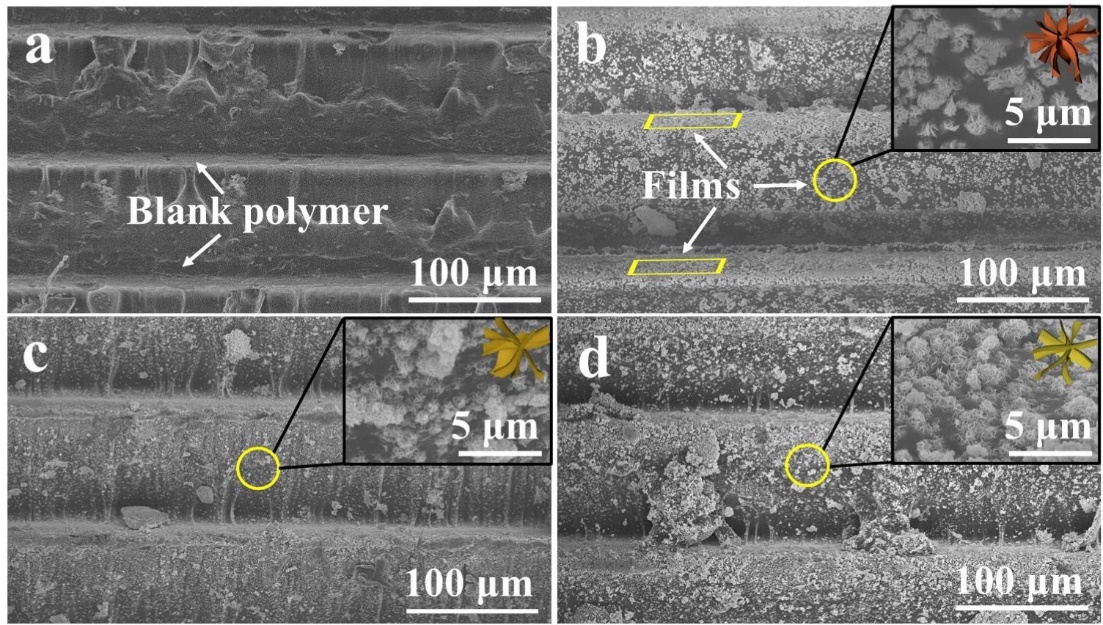

Researchers found that the substrate was completely covered with floriform microstructure film. During the in-situ grown process of the film, OH-/I substitution strategy was introduced to fabricate I-defects engineering BiOI film. The superficial color of the 3D-printed substrates ordinally changed from gloss white to brownish yellow, dark yellow, and light yellow, which was ascribed to the change of band gap caused by iodine defect engineering film.

In the grown process of films, iodine spaces were introduced into the BiOI crystals, causing BiOI internal electric field and electron density increase and improve the photoinduced carrier separation and transmission efficiency. Iodine defects engineering BiOI exhibited smaller grain size, higher specific surface area, electronegativity, photoelectric response and photocatalytic activity than stoichiometry BiOI.

Researchers thought Bi3+ firstly adsorbed on polymers to construct the active grown sites of the film. With the extension of time, the films gradually self-assembled into petal-like BiOI film. High proportion and movement speed of I- promoted the in-situ grown of BiOI film along the (110) crystal plane.

"The film exhibits good photocatalytic activity and cyclic stability on photodegrading organic compounds and sterilizing microorganism possessed," said XU Xuelei, first author of the study.

"This is another breakthrough after the team developed bismuth based photocatalytic films on polyvinyl chloride and epoxy resin," said by Prof. ZHANG, corresponding author of the study.

This research was supported by National Natural Science Foundation of China, High-end Users Program of "Kexue", China Postdoctoral Science Foundation and Nantong Scientific Plan Foundation.

Fig. 1 The scheme of in-situ photocatalytic film on 3D-printed polymer as an efficient purification application.

Fig. 2 Scanning electron microscopy (SEM) images of (a) the blank polymer substrate and I-defect engineering films fabricated at (b) pH 2.48, (c) pH 4~6, (d) pH 6~9.

Xu, X., Wang, Y., Zhang, D. (2023). In-situ growth pH-adjusted iodine defects engineering BiOI film on 3D-printed polymer substrate for efficient organic pollutant and microorganism purification. Separation and Purification Technology.

(Text by XU Xuelei & WANG Yi)

Media Contact:

ZHANG Yiyi

Institute of Oceanology

E-mail: zhangyiyi@qdio.ac.cn

(Editor: ZHANG Yiyi)