New Strategy Boosts Performance of Hydroisomerization

The n-paraffin hydroisomerization catalyzed by bifunctional catalysts is an atom-economic reaction and one of the most important reactions in chemical industry.

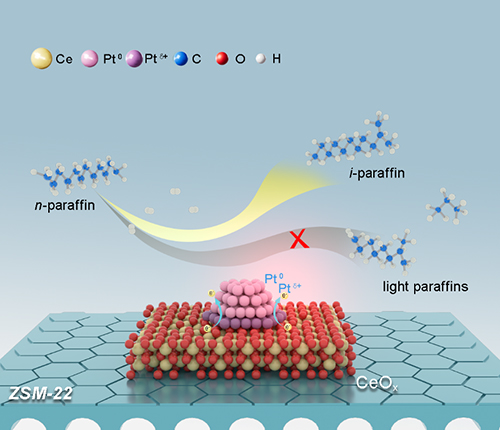

Bifunctional catalyst used in this reaction contains an acid function and a noble metal function. The balance of these two functions is the key for the high catalytic performance. Without this balance, the isomerized carbonium ions formed on acid sites will undergo subsequent cracking, giving rise to light alkanes.

Recently, a research group led by Profs. TIAN Zhijian and WANG Congxin from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) has developed a new strategy to elevate the intrinsic property of metal function and prepared a highly-efficient PtCeOx/ZSM-22 catalyst for n-paraffin hydroisomerization reaction. They also revealed the structural feature of Pt, as well as the nature of the high intrinsic activity.

The study was published in Chem Catalysis on Jan. 26.

The electron transfer pathway and n-paraffin conversion scheme on the PtCeOX/ZSM-22 catalyst (Image by WANG Congxin)

The researchers proposed a facile sequential impregnation method by taking advantage of the discrepancy in point of zero charge between ZSM-22 support and ceria additive, through which the CeOx species were formed across the rod-like ZSM-22 support and Pt nano clusters were anchored on the surface of ceria.

They found the electron transfer between Pt and CeOx. This electron transfer effect brought a significant elevation for the intrinsic activity of the catalyst. It enabled Ptδ+ species to quickly activate C-H bonds in the initial dehydrogenation of alkanes step and donate the electron to saturate the branched alkenes in the terminal hydrogenation step of n-paraffin hydroisomerization process.

This catalyst (0.3wt%PtCeOx/ZSM-22) showed high performance in n-paraffin hydroisomerization with enhanced turnover frequency, a high isomer selectivity (96%) at high n-paraffin conversion rate (91%), and an 87% i-paraffin yield which was superior to the ever-reported commercial Pt/ZSM-22 catalyst with traditional high Pt content (no less than 0.5wt% Pt).

"This work provides not only new insights in Pt-metal oxide interaction in bifunctional catalysts, but also strategy for efficient bifunctional catalyst manufacture in potential industrial applications," said Prof. WANG.

The above work was supported by the National Key R&D Program of China, the Strategic Priority Research Program of CAS, and the Youth Innovation Promotion Association of CAS.