Study Sheds Light on Corrosion Characteristic and Mechanism of Magnesium Alloys in Marine Atmospheric Environment

With the rapid development of ocean exploration in the world, magnesium structural materials are gradually served in typical marine environment. In the marine atmospheric environment, the problem of electrochemical corrosion of magnesium alloys is very prominent due to the activity of magnesium element.

The corrosion of magnesium alloys occurs easily in the south China Sea environment because of the specific high temperature, high humidity, high sea salts and high ultraviolet radiation. Corrosion leads to the failure of materials and structures, which causing the large economic loss. Therefore, a major research issue of magnesium alloys is their corrosion behavior in this typical marine atmospheric environment.

Recently, the research team led by Prof. HOU Baorong from the Institute of Oceanology of the Chinese Academy of Sciences (IOCAS) researched the corrosion behavior of Mg-Y-Nd-Zn-Zr magnesium alloys in the harsh South China Sea environment.

The study was published in Journal of Magnesium and Alloys on May. 5.

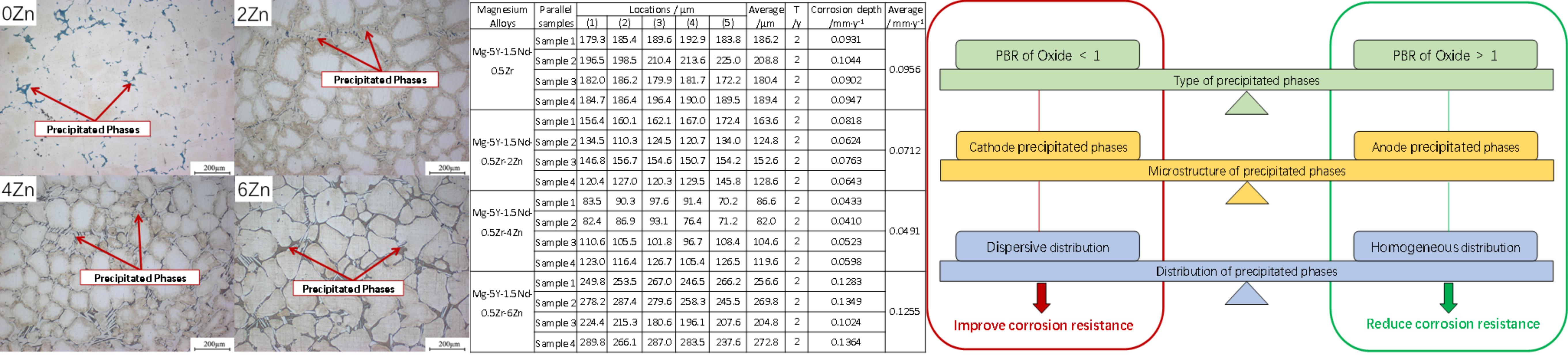

The corrosion resistance of different alloys was also analyzed via weight loss rate and electrochemical measurement in the laboratory. Mg-5Y-1.5Nd-xZn-0.5Zr magnesium alloy existed the best corrosion resistance which depended on the microstructure, type and distribution of precipitated phases. The corrosion resistance of the magnesium alloys in the typical marine environment was as followed: Mg-5Y-1.5Nd-6Zn-0.5Zr < Mg-5Y-1.5Nd-0.5Zr < Mg-5Y-1.5Nd-2Zn-0.5Zr < Mg-5Y-1.5Nd-4Zn-0.5Zr,which was closely related to the types, microstructure and distribution of precipitated phases.

The microstructure of alloys was investigated in order to explain corrosion mechanism. The standard electrode potential of rare earth elements (Y=-2.372V, Nd=-2.431V) is more negative than that of pure magnesium (-2.363V). The precipitated phases in Magnesium alloys contained rare earths have the micro-anode influence. Some special anodic precipitated phases exhibit a biaxial synergistic effect, micro-galvanic corrosion acceleration and corrosion barrier. This can improve the corrosion resistance of magnesium matrix to some extent.

"The need and the requirement of materials corrosion testing in the marine environment was analyzed from the aspects of the ocean exploited and military applications. In the corrosion process, both anodic precipitated phase and cathodic precipitated phase in magnesium alloys showed the dual effect," said JIANG Quantong, first author of the study.

"Regulating the microstructure, type and distribution of precipitated phases in magnesium alloys contained rare earth to improving both the mechanical strength and corrosion resistance need a further study," said Prof. HOU.

The research was supported by National Natural Science Foundation of China for Exploring Key Scientific Instrument, the Open Funds of the State Key Laboratory of Rare Earth Resource Utilization and Hainan Province Science and Technology Special Fund for providing support.

The microstructure, corrosion rate and corrosion mechanism of Mg-Y-Nd-Zn-Zr magnesium alloys in the harsh South China Sea environment

Jiang Q.T., Lu D.Z., Cheng L.R., Liu N.Z., Hou B.R. (2022). The Corrosion Characteristic and Mechanism of Mg-5Y-1.5Nd-xZn-0.5Zr (x=0, 2, 4, 6 wt.%) Alloys in Marine Atmospheric Environment. Journal of Magnesium and Alloys.

JIANG Quantong

Institute of Oceanology

E-mail: jiangquantong@qdio.ac.cn

(Editor: ZHANG Yiyi)