Mössbauer Spectroscopic Technique Enables Precise Characterization of Single Atom Iron Catalyst

Recently, Prof. WANG Junhu's group from the Dalian Institute of Chemical Physics (DICP) of CAS, in collaboration with Prof. Jong-Beom Baek's group from Ulsan National Institute of Science and Technology (UNIST), realized the precise characterization of mechanochemically prepared single atom iron catalyst by using Mössbauer spectroscopy technique.

This work was published in Nature Nanotechnology on Feb. 7.

In the mechanochemical method, the bulk metal is applied as precursor rather than metal salts. No solvent is adopted, and there was even no water, no any byproducts nor wastes.

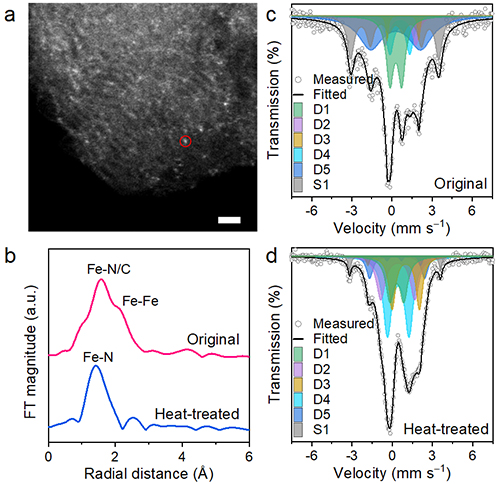

However, in the prepared single atom catalyst, there still exists occasionally formed metal clusters. Since these clusters are very less and only short-range ordered, even the high resolution extended X-ray absorption fine structure spectroscopy (EXAFS) is hard to quantitatively and qualitatively identify them.

In this study, the researchers resorted to 57Fe Mössbauer spectroscopy to reveal the coordination environment of Fe (mainly composed of Fe4N species), and detected a small amount of Fe clusters identified as Fe3C (S1), which were difficult to be found in other characterizations.

After heat-treatment purification, even the content of Fe3C was only 4%, it could also be easily detected by Mössbauer spectroscopy.

"Our studies demonstrated that Mössbauer spectroscopy is one of the most important techniques to characterize the purity of single atom Fe," said Prof. WANG.

Characterizations of Fe–N–C single atom catalysts (Image by HAN Gaofeng)

This work was supported by the National Key Research and Development Program of China, the National Natural Science Foundation of China, and the International Partnership Program of CAS. (Text by HAN Gaofeng)