New Catalytic Approach Directly Converts Raw Biomass into Natural Gas with Low Carbon Footprint

Natural gas can be used as fuel for generating electricity, heating and powering transportation. It is also the raw material to manufacture hydrogen and ammonia.

Currently, biogenic and thermogenic processes are the two widely accepted methods for natural gas production. Whereas, high content of CO2 in gas products is inevitable during these processes, which cannot satisfy the composition requirements of pipeline natural gas.

A research group led by Prof. LU Fang from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) proposed an efficient catalytic approach to directly transfer solid biomass into natural gas with low carbon footprint.

This study was published in Nature Communications on January 11.

The researchers prepared a robust catalyst with Ni2Al3 alloy phase, achieving nearly complete conversion of various agricultural and forestry to natural gas. In the conversion process, the total carbon yield of gas products reached up to 93% after several hours, and the catalyst showed powerful processing capability for the production of natural gas during 30 cycles.

"Life cycle assessment revealed that the life cycle primary fossil energy depletion and greenhouse gas emissions in this process could be reduced by 26% and 34%, respectively, compared to the fossil-natural gas," said Prof. LU.

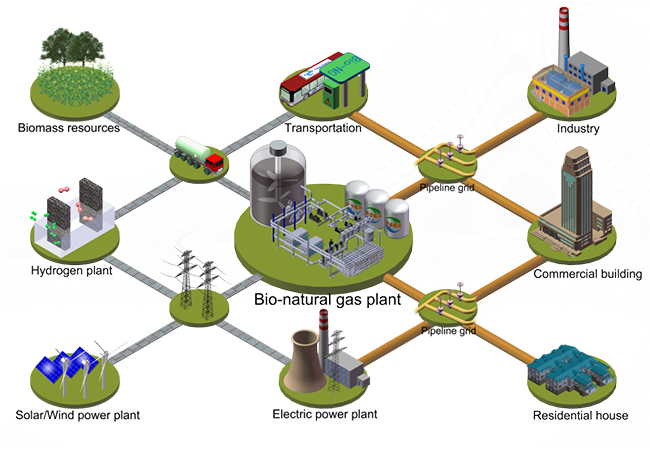

Conceptual diagram for bio-natural gas production from biomass (Image by SI Xiaoqin)

What's more, bio-natural gas produced from the combined hydrogen with lignocellulosic biomass can be further applied in industry, transportation, and electric power plant by the existing transportation pipelines.

This study provides a new guidance for the catalytic transformation of raw biomass. It was supported by the Natural Science Foundation of China, the National Key R&D Program of China, the Strategic Priority Research Program of CAS, and DICP Grant. (Text by SI Xiaoqin)