High-performance Potassium Ion Micro-supercapacitors Developed for Wearable Pressure Sensor System

The development of flexible, wearable and implantable microelectronics has accelerated the need for miniaturized and integrated energy storage devices with mechanically robust properties, high voltage, and highly compatible integration.

Micro-supercapacitors (MSCs) have ultrahigh power density, fast charge and discharge rate, and long life stability, which hold a great potential for microelectronics. However, they suffer from relatively low energy density and narrow potential window.

Recently, a research team led by Prof. WU Zhongshuai from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences developed a new prototype of high-performance potassium ion micro-supercapacitors (KIMSCs) to power the sensitively integrated pressure sensing system.

This work was published in Advanced Energy Materials on March 18.

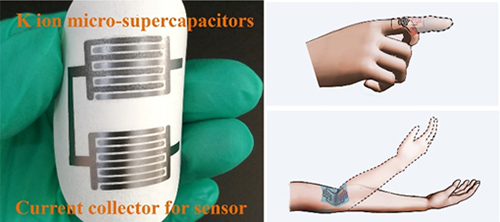

Schematic of preparation of MXene-derived KTO nanorods and the fabrication of the integrated KIMSC-sensor system (Image by ZHENG Shuanghao)

The KIMSCs take MXene-derived potassium titanate (KTO) nanorods as negative electrode and porous activated graphene (AG) as positive electrode in a non-flammable high-voltage ionogel electrolyte, which serves as a sufficient microscale power source for the construction of an integrated sensor system.

The researchers prepared the KTO nanorods from the simultaneous alkalization and oxidation of Ti3C2 MXene via hydrothermal method. The KTO delivered a considerable diffusion coefficient of 1.6 × 10-12 cm2 s-1 and high capacity of 145 mAh g-1 as anode materials for K ion storage. The as-fabricated KIMSCs could offer a large operating voltage of 3.8 V, extraordinary volumetric energy density of 34.1 mWh cm-3, and mechanical robustness.

Moreover, they designed a highly integrated system based on KIMSC and a pressure sensor for efficiently monitoring the body movement of elbow and finger.

This work was supported by the National Natural Science Foundation of China, Dalian National Laboratory for Clean Energy of CAS. (Text by ZHENG Shuanghao and MA Jiaxin)