Demonstration of novel-concept Pd composite membranes and its applications in NH3 decomposition membrane reactor

Researchers led by Prof. LI Hui, Prof. CHEN Ping and Asso. Prof. LIU Lin from Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences has successfully demonstrated novel Pd composite membranes with a finger-like and gap structure and its application in NH3 decomposition membrane reactor. Their studies were published in the journal Chem. Eng. J.

Due to unique permeability to hydrogen and its isotopes, Pd-based membranes play an important role in ultrapure hydrogen generation in semiconductor industry as well as pure hydrogen production for fuel cell application in both vehicular and stationary scenarios.

The thermal/chemical stability remains the most critical challenge towards the commercial application of Pd-based composite membranes. Under fuel cell application conditions, the fast response requirements during startup/shutdown process further imposes a high demand on the stability of Pd composite membranes. Thermal stresses may exist between Pd layer and membrane module as well as between Pd layer and porous substrate underneath, which need to be taken into account.

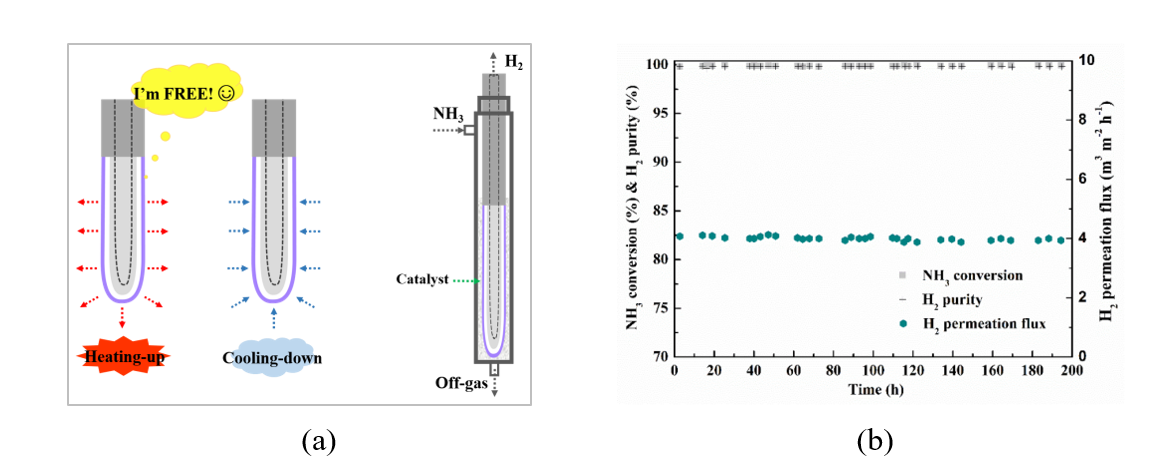

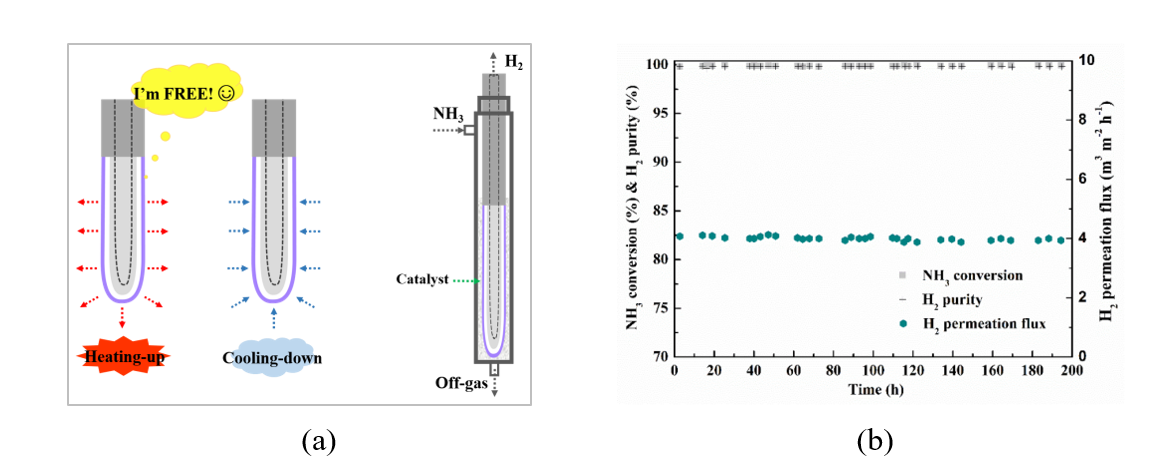

(a) The schematic of novel-configuration Pd composite membrane and NH3 decomposition membrane reactor, (b) A long-term stability test of 200 h of Ru-catalyzed NH3 decomposition Pd membrane reactor at 673 K. (Image by LI Hui, LIU Lin)

This study presents a facile and effective approach to develop high performance stainless-steel supported Pd composite membranes with a finger-like and gap structure by coating the finger-like porous stainless-steel support (PSS) with MnCO3 particles, which forms a small gap of ca. 1 μm during subsequent thermal treatment.

The stability of this novel configuration was demonstrated under 20–50 fast heating up/cooling down cycles at a maximum ramp rate of 10 K/min, under near practical fuel cell application conditions. Such a structure imitates semi-free-standing bulk Pd membranes, which not only avoids the direct contact between Pd layer and PSS and ensures a high H2 permeance, but also avoids the shear stresses between the metal membrane and module.

The membrane with a finger-like and gap structure was applied in NH3 decomposition membrane reactor, which achieved nearly complete NH3 conversion at a relatively low temperature of 673 K and remained stable for 200 h, exhibiting potential in future applications.

This work was supported by the 100-Talent Project of CAS, National Natural Science Foundation of China (Grant No. 21676265; 51501177; 21306183), The Ministry of Science and Technology (MOST) of the People's Republic of China (Grant No. 2016YFE0118300), and the K. C. Wong Education Foundation (GJTD- 2018-06). (Text by LI Hui, LIU Lin)