Laser peening technology has matured into a fully qualified production process designed to improve the performance and fatigue life of work-pieces, and will enable designers to consider higher stress levels in life limited designs. Laser peening can be used to prolong the fatigue life of aerospace, automotive, power generation, nuclear waste disposal, petroleum drilling, medical implants and recreational sports. In the aerospace industry, this surface technology starts to be applied to the tip of fan blades inside air craft engines with the aim of saving the fatigue failure by foreign object damage.

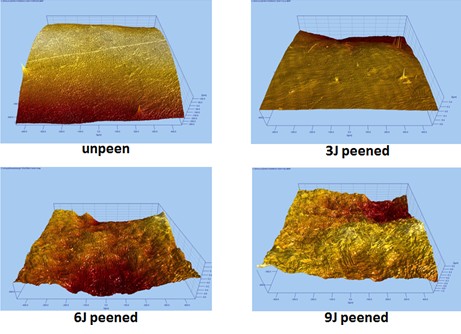

To improve the life of air craft engines, researchers from Shenyang Institute of Automation (SIA), Chinese Academy of Sciences developed blisk laser peening device in 2009. The blisk laser peening device serves in AVIC Shenyang Liming Aero-engine (Group) Corporation LTD, now. The blisk laser peening device is shown in Fig.1. The device has capability of 130 watts average power, a pulse width of 15 to 20 ns, pulse energy to 25J, a repetition rate to 4 Hz, and a nominally rectangular laser-spot profile.Using the blisk laser peening device, the researchers have studied the effects of laser peening on residual stress distributions and deformation microstructure of TiAl alloy. The MicroXAM-1200 3D non-contact optical profilers were used to measure the surface roughness of peened samples. Fig.2 shows that surface roughness of peened samples increase with laser energy. High laser peening energy generate rougher surface.

Fig.1 Photo of blisk laser peening device (Image provided by Qiao Hongchao)

Fig.2 Surface roughness of laser peened samples increase with laser energy (Image provided by Qiao Hongchao and Zhao Yixiang)

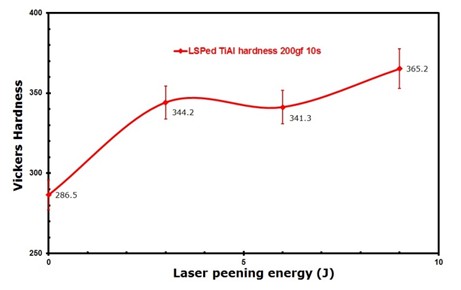

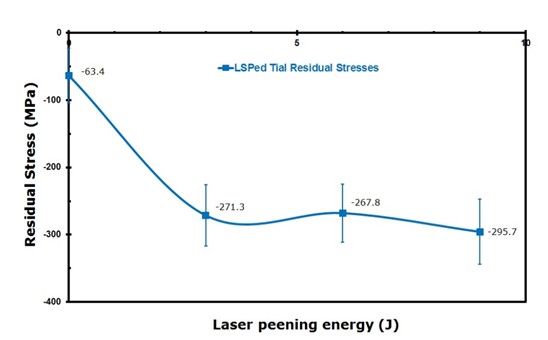

Fig.3 shows the surface Vickers hardness of virgin material and laser peened samples. The virgin one has 286.5 HV value. The peened samples hardness values increase to more than 340 HV. Fig.4 shows the residual stress of virgin material and laser peened samples. Convectional XRD was used to measure the residual stress values at the sample surface. Virgin one has low compressive residual stress value of -63Mpa. The peened ones increase to more than 250 MPa compressive residual stresses. Conclusions: Surface roughness of laser peened TiAl samples increase with laser energy. Higher laser peening energy generates high surface hardness and compressive residual stress.

Fig.3 Surface residual stress vs. laser energy (Image provided by Qiao Hongchao and Zhao Yixiangl)

Fig.4 Surface roughness of laser peened samples increase with laser energy (Image provided by Qiao Hongchao and Zhao Yixiang)

This work was presented on the 4th International Conference on Laser Peening and Related Phenomena (ICLPRP) in Madrid in May 2013. The ICLPRP is held every two years, and is the world’s top conference on laser peening. The aim of ICLPRP is to provide a forum for the discussion of latest innovations and studies in laser peening and their application to industrial sectors among scientists and engineers from all over the world. According to the real importance of the basic physical foundations of the technique, the scope of the Conference is naturally open to include contributions relating to basic phenomena, alternative methods, residual stress measurement, etc. in order to increase the understanding of underlying physics of the technique and promote further applications.

CONTACT:

Professor: ZHAO Jibin

Associate professor: QIAO Hongchao

Shenyang Institute of Automation, Chinese Academy of Sciences

Email: hcqiao@sia.cn

Tel: 024-83601252